UPDATE: The loveseat plans and guidance can be found HERE

You may recall a previous post wherein I declared a goal of erecting 100 bluebird nesting boxes around our property. The progress on that project has been satisfactory. To date, I have built 65 nesting boxes: 50 have been erected along our trails, 3 were given to others, and 12 remain in my shop, awaiting my ambition to pound more t-posts into the ground.

Since then, I have taken a short break from building nesting boxes in order to complete a couple of other quick projects. First, there was the benchtable, the subject of my last post. And now, I have just finished this Adirondack style love seat.

Well, it really isn’t finished, because to truly be called finished, I must apply some kind of finish to the love seat – then it will be, quite literally,  finished. But it’s close enough.

I intended to build this love seat from plans obtained from a book Retta purchased some time ago. After buying the necessary materials for the project, the next step was the preparation of the templates I would use to produce uniform, accurate parts. It turns out the author of the book, or the editor, or both, did not check the construction plans for accuracy and/or completeness. It soon became apparent that many critical dimensions and cutting angles were omitted from the plans.

Determined to build this love seat, I pressed forward, figuring (correctly, as it turned out) the worst that could happen would be a little wasted time and lumber. The photograph above shows the contoured seat bottom assembly that had to be built, but because the plans offered little assistance, a lot of guess work (and wasted lumber) went into building this part of the seat.

The love seat is made from 1″ stock (5/4 x 6″ pressure treated deck boards), and feels quite sturdy.  It is designed with a series of three seat supports and substantial bracing, as you can see from the picture above.

The reason I decided to build this seat, even though the plans were deficient, was that the design promised to be extremely comfortable, with the contoured seat bottom that I mention before, as well as the contoured seat back, which is evident in the photograph above.

Even though I spent a lot of extra time, and wasted some lumber experimenting in order to get the seat angles just right, the project turned out to be well worth the effort. This is one of those pieces that, once seated, you just don’t want to get up out of, due to it’s very comfortable design. Now that I have a working sample in front of me, I will build accurate templates, so that I can build several at a time and scatter them around the property (along with all the bluebird nesting boxes and benchtables ;)

___________________________

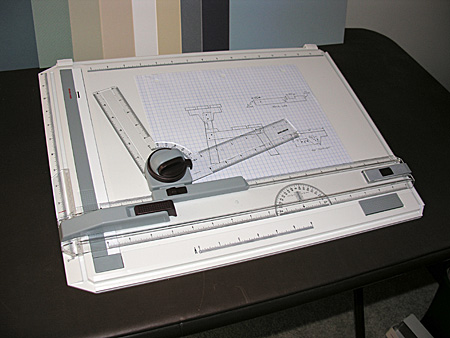

In commenting on the Benchtable post, Karl suggested that I upload plans for the benchtable, so that they may spread throughout the Ozarks. As it happens, I recently ran across a wonderful little drafting board while at Grizzly Industrial  in Springfield, Missouri.

Now, once I brush up on my mechanical drafting skills, I’ll try to figure out how to post the plans on-line for those who may wish to build something in their spare time.