A few day ago Retta and I had to leave her vehicle at the local Ford dealer for some maintenance, which was going to take a few hours for the dealership to complete. We decided to kill the time by sightseeing in our local area, which took us south along Arkansas Scenic Byway 7, which is always a lovely and picturesque drive.

Because we hadn’t eaten anything prior to leaving the house, we thought it would be a fine idea to partake of breakfast at the Cliff House Inn, a well-known (among locals) diner located in a spectacular location along the scenic route.Â

Besides good food at a fair price, the main draw of the Cliff House Inn is the view that can be seen from the dining room and from the casual balcony, shown in the photograph above.

The Cliff House Inn overlooks a scenic canyon, which, according to the sign above, is the deepest canyon in the Ozarks.

While this canyon certainly cannot compete with the Grand Canyon in scope and drama, it is still a beautiful and very delightful sight to view while savoring a meal at the Inn. In the photograph above, you can see the view from the balcony on a day when a typical Ozarks fog bank filled the canyon. By the time we had finished our breakfast, the fog had dissipated, offering a clear view of the surrounding hills and valleys (hollers, as they’re known around here).

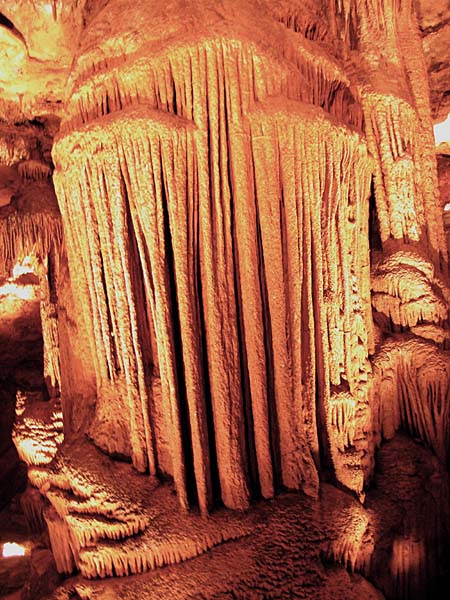

After breakfast at the Cliffhouse Inn we traveled back toward town. Northern Arkansas is home to over 4700 identified caves, owing to the Swiss cheese-like geology of the schist formations that form the Ozarks. Along the way we passed one of these caves, Mystic Cavern, which operates daily guided cave tours, and so we elected to kill some more time by taking a cavern tour. As we waited for the guided tour to begin, we browsed the gift and rock shop on the premises, where we saw this amazingly large amethyst geode from Brazil (asking price – $2700).

Inside Mystic Cavern you can see all of the various types of cave formations you would expect to see in such an environment. It was well worth the time and minor effort involved for us to see this cavern.

Between breakfast at the Cliff House Inn and a tour of Mystic Cavern, we thought it was time to start heading back to town, but not without one more quick stop along the way.

We would be crossing a section of the Buffalo National River, a scenic waterway administered by the U.S. National Park Service as the first U.S. National River. The Buffalo River is a superb and popular river for float trips. Besides the solitude and seclusion the river offers, the main draw is the pristine beauty of the crystal clear water gently flowing along cliffs and rock embankments like the one shown in the photograph above. When the water is calm, it is hard to tell where the water begins and the rock ends. We wouldn’t think of driving by the Buffalo River without stopping to take a look, which is exactly what we did before returning to town to pick up Retta’s vehicle from the dealership.

It is a very nice feeling knowing that we can enjoy such a wonderful and scenic day by just driving around the very area we choose to make our home.