We are fortunate to have several ponds scattered around our property. Previously, I had written about three of them: the catfish pond (remember the discussion about flocculant?), the carp pond (recall “The Grassing of the Carp”), and the spring-fed pond (which shrank dramatically during the dryness of last year).

There is another pond on the property, which is the subject of this post. I call it the “people pond.”  As caretakers of the land and stewards of the animals, we strive to provide an aquatic environment conducive to the well-being of all the wildlife that reside at this location – so why not the human inhabitants, as well?

Unlike the other ponds on the property that automatically adjust themselves to exist in all seasons throughout the year, the people pond needs a little extra effort and management. In the fall, the people pond needs to undergo the process of winterizing. The people pond must be cleaned, and the water chemistry adjusted for the long winter to come. Pipes, pumps, filters and other equipment must be drained of all water, to prevent expansion damage that would occur if water were allowed to freeze inside of the equipment. The water level is drawn down, and the people pond is covered for the duration of the cold season.

In the late spring, usually around Memorial Day weekend, we anxiously undertake the annual ritual of opening up the people pond for the summer.

The winter safety cover shown in the photograph above serves two purposes. First, it serves to protect against accidental people pond incidents, and second, it keeps dirt, leaves and debris out of the people pond during the winter months. In the center of the cover sits a sump pump, equipped with an automatic sensor switch, which keeps the cover drained of water from rain and melting snow.

The cover is attached to the decking that surrounds the people pond by a series of heavy elastic straps, which are held in place by bronze retractable anchors embedded in the deck.

The retractable anchor tend to accumulate debris over the course of the winter, so it is necessary to wash them off with a strong stream of water from the garden hose.

Before screwing the anchors flush into the deck, I find it helpful to spray them with a little lubricant first. The product that I like to use for this purpose is either Bull Shot, shown above, or Boeshield T-9, developed by Boeing Aircraft Corporation. Either one of these products contain a wax-like ingredient, which assures that the protectent will adhere to the anchor even in wet conditions.

The turquoise gizmo that you see beside the skimmer assembly is just that – a Gizmo ™. This device is used to seal the water return lines in the winter, after they have been cleared of water. If you look closely at the photograph above, you can see the hole down at the bottom of the skimmer that the Gizmo screws into. With the Gizmo properly in place, any rain water that manages to get into the skimmer and freeze will not ruin the equipment. As the freezing water expands, it will cause the Gizmo to collapse in on itself, thus sparing the skimmer from damage.

The people pond cover needs to be cleaned and thoroughly dried prior to summer storage. As you can see from the photograph above, it is not particularly good form to be standing around taking pictures as your better-half does all the work! Thank goodness for the blur function of my image editing software, or you might see the “salute” I received for my blunder.

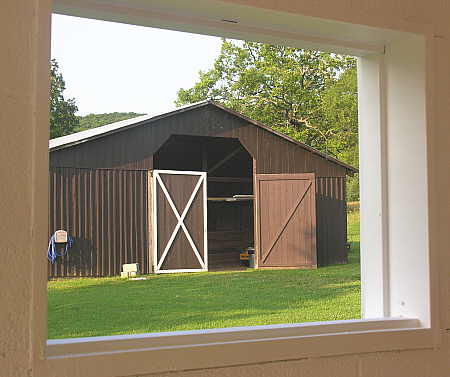

The people pond cover folds nicely into a breathable nylon storage bag, which will find it’s way into the equipment barn for the summer.

Now that the cover is off the people pond, all that remains is to raise the water level, adjust the water chemistry, prime the pump and filter units, and install the hand rails and exit ladder. Notice the clarity of the water in this picture. This is what the water should look like immediately upon removing the people pond cover. If the water does NOT look like this, then somebody did not properly adjust the water chemistry prior to winterizing the people pond the previous fall.

Our people pond has been quite a project. Compare the photograph above with the picture that is shown below.

This is what the people pond looked like when we bought this house. It was in dire need of some TLC, needing a new liner, winter safety cover, pump and other necessary equipment. The water was filthy and gross, containing slime, algae and assorted creatures. It did not deserve to be called a people pond. Now it does.