This morning, after finishing my cup of coffee, I headed outside to begin my chores. George (our faithful yellow lab) accompanied me as I made my way over to the milking barn, where I spotted this lovely Luna moth that you see in the photograph above.

The Luna moth was resting on the back door of the milking barn, and seemed to be completely oblivious to my presence. He ended up spending most of the morning clinging to the door, perhaps taking advantage of the shade on that side of the building.

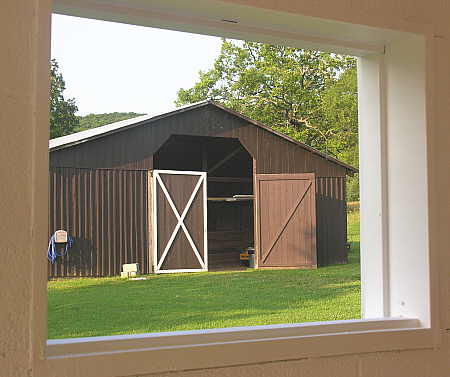

This is what the milking barn looked like when we first bought this property. It was in pretty poor shape, and was being used to store mostly junk. Step-by-step, we have been undertaking a renovation of this building.Â

We are now converting the front room into a tack room ( a room where we will store saddles, pads, blankets, bridles, halters, leads, crops, carrot sticks, reins, bits, farrier tools, brushes and combs, fly spray, medications, and all the hundreds of other things you find are necessary to keep horses).

Here is the front of the milking barn as it looks today. We call this the “milking barn” because it was built and used as dairy barn in the past. This 36′ x 25’ building is constructed from cinder block, and is comprised of two equally sized 18′ x 25′ rooms. The room toward the front of the building (with the full-length windows) formerly contained a stainless steel milk storage tank, and was thus called the “tank” room. The milk was picked up every other day by a dairy wholesaler, who transported the product to a major milk processor.

This is the rear portion of the building, which is where the cows would be milked daily. The room on this side of the barn was obviously called the “milking” room. Inside the milking room were eight stalls arranged in a herring-bone pattern on either side of the room. In the center of the room was a four foot deep milking pit, where the person doing the milking would stand to work, much like the pits that are used in an oil-change garage for the mechanic to position himself under the vehicle. Grain was stored in hoppers located in the attic above the milking room, and a system of chutes would automatically supply strategically placed feed troughs with grain for the eight cows being milked.

We are in the process of converting this room into a workshop, so that I will have no excuse to not get my equipment maintenance and repairs done in a timely manner.

Excuse all the things laying around on the floor, but I just completed the painting of the inside of the new “shop” this morning. In the picture above, you can see where the 4′ deep milking pit used to be located. We have filled in the pit with tons of gravel, and topped it off with a 5″ reinforced concrete slab. Now that the shop has been painted, I will install work benches and storage shelving. After that, I will plan out and install conduit for 110v/220v electrical service to locations around the shop, where I will place my compressor, drill press, etc.

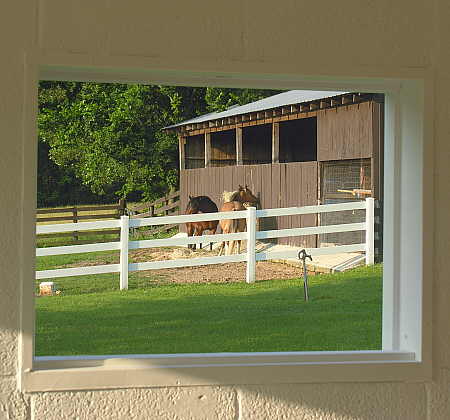

The shop is in a great location far from the house, so noise from power tools and equipment will not be a bother to residents in the house. The horses, which I can keep an eye on through the many windows in the shop, may not like the noise, but they can always stroll over to another pasture if it is bothersome to them.

I can also keep an eye on the equipment barn, which is located out another of the shop windows.

The hen house (sorry, it’s still not repainted yet) is in view of the shop, so I can keep a watchful eye on things over there, as well.

And all the while, my trusty “helpers” can keep a keen eye out for me, too. They certainly wouldn’t want to miss any of my foibles, as I run amok in my new shop!

That looks like it is going to be a pretty nice shop. When are you coming up to build mine?

I once converted a hen house into a honey house where we extracted thousands of pounds of honey. It’s amazing what one can do with a little elbow grease and imagination.

How will you ever get any work done if you’re keeping your eye on everything that is going on outside? That are you going to do with the pit in the milking area?

Ed – Just give the word, and I’ll be right up with my tool belt and hammer.

Pablo – That’s the whole point – I won’t get any work done, but at least it will go undone in a nice shop with a view 🙂

We have already filled in the pit with gravel and a concrete slab, so now I won’t fall into a hole as I walk from one side of the shop to the other, looking out the windows (while not working, of course).

Catching up while I am at a broadband connection. My dialup was not handling your travel photos very well.

That’s a great shop in progress. Very bright and roomy.

RE: previous post about the islands, my old high school chum is the superintendent of Channel Islands … unless some recent transfer has occurred.

Great job. It looks nice enough to live in. I know you will be using it a lot. I really like the light colors. As I get older any dark color seems to suck the light out of the air.

Pingback: Ranch Ramblins » Blog Archive » Deferred Maintenance